Enye yeenzuzo ezinkulu ekusebenzeni noYi Zheng lulwazi lwethu olupheleleyo lwenkqubo;asizizo iingcaphephe kwinxalenye enye yenkqubo, kodwa noko, onke amacandelo.Oku kusivumela ukuba sinikeze abathengi bethu imbono ekhethekileyo malunga nendlela inxalenye nganye yenkqubo eya kusebenza ngayo kunye xa iyonke.

Sinokubonelela ngeenkqubo ezipheleleyo zegranulation, okanye iziqwenga zezixhobo zomntu ngamnye kuzo zombini usetyenziso lwe-inorganic kunye ne-organic.

Sinokubonelela ngoyilo lwenkqubo kunye nonikezelo lwalo lonke umgca wokuvelisa isichumiso ongasomisi.Izixhobo zazibandakanya i-Hopper & Feeder, i-roller (i-Extrusion) iGranulator, i-Rotary Screen, i-Bucket Elevator, i-Belt Conveyor, i-Packing Machine kunye ne-Scrubber.

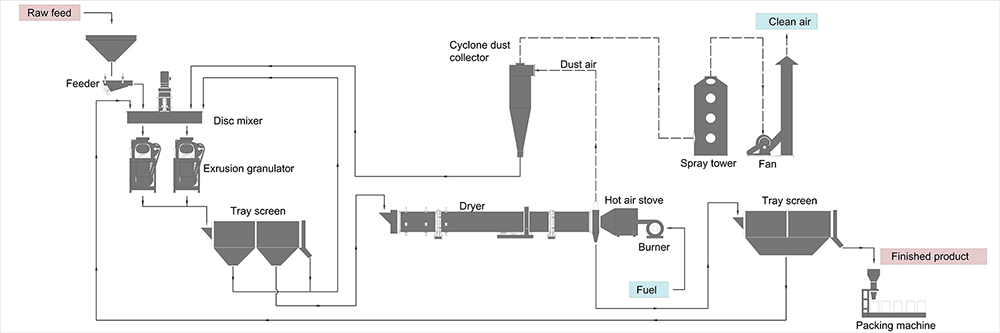

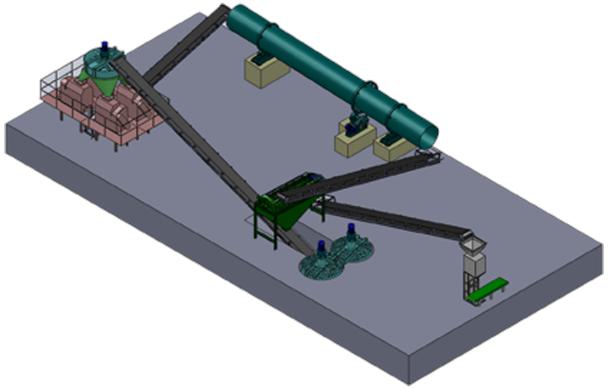

Oku Umgca wokuvelisa i-roller (I-Extrusion) yegranulator inokuvelisa isichumiso esixutywe phezulu, esiphakathi nesisezantsi esixutywe kakhulu kwizityalo ezahlukeneyo.Ngegranulator ephindwe kabini ukuvelisa i-granules, umgca wemveliso awufuni inkqubo yokomisa, unotyalo-mali oluncinci kunye nokusetyenziswa kwamandla aphantsi.Iirola zokushicilela zegranulator zinokuyilwa ukwenza iimilo ezahlukeneyo kunye nobukhulu bezinto.Umgca uquka umatshini wokudibanisa ozenzekelayo, abathumeli bebhanti, abaxube be-pan, i-pan feeder, i-extrusion granulators, umatshini wokuhlola ojikelezayo, indawo yokugcina imveliso egqityiweyo, kunye nomatshini wokupakisha ngokuzenzekelayo.Sikulungele ukubonelela ngezona zixhobo zithembekileyo zesichumiso kunye nezona zisombululo ezifanelekileyo kubathengi bethu abahloniphekileyo.

Izinto eziluncedo:

1. Yamkela uxinzelelo lomatshini ukwenza iigranules, akukho mfuneko yokufudumeza okanye ukufumisa imathiriyeli ekrwada

2. Ifanele izinto ezibuthathaka kubushushu, ezifana ne-ammonium bicarbonate

3. Akukho mfuneko yokumisa inkqubo, utyalo-mali oluphantsi, ukusetyenziswa kwamandla aphantsi.

4.Akukho manzi amdaka okanye ukukhutshwa kwegesi eyinkunkuma, akukho kungcoliseka kwendalo.

5. Ukuhanjiswa kobungakanani besuntswana elifanayo, akukho agglomeration.

6. I-Compact layout, iteknoloji ephezulu, ukusebenza okuzinzileyo, ukulungiswa okulula.

7. Ukusebenza okulula, kulula ukuqonda ulawulo oluzenzekelayo, ukwandisa ukusebenza kakuhle kwemveliso.

8. Uluhlu olubanzi lwesicelo sezinto eziluhlaza, akukho mfuneko yepropati ekhethekileyo

Pirowusi

1. Umatshini wokudibanisa ozenzekelayo

Okokuqala, izixhobo ezahlukeneyo zilinganiswe ngokwefomula ngumatshini wokubetha weebhini ezi-5, onokuzalisa imathiriyeli ngokuzenzekelayo ngokuchaneka okuphezulu kunye nokusebenza okuphezulu, ngaloo ndlela umgangatho wesichumiso uyaqinisekiswa.Emva kokudibanisa, izixhobo zihanjiswa kwi-pan mixer.

2. Umxubi weDiskhi

Samkela iiseti ezimbini zabaxube bediski kulo mgca wokuvelisa isichumiso.I-cycloidal reducer iqhuba i-shaft engundoqo ukuba ijikeleze, kwaye iqhube iingalo eziphazamisayo.Ngokuxutywa kweengalo eziphazamisayo kunye neefosholo ezincinci kuzo, izinto eziluhlaza zixutywe ngokupheleleyo.Emva kokuxuba, izinto eziphathekayo zikhutshwa kwi-outlet ezantsi.Icala elingaphakathi le-disc lithatha ipleyiti ye-polypropylene okanye insimbi engenasici, eyenza ukuba izinto eziphathekayo zingabi lula, kunye nokuxhatshazwa kwe-abrasion.

3. I-Double Roller Fertilizer Granulator

Ngomthumeli webhanti, izinto ezixutywe kakuhle zekrwada zigqithiselwa kwi-pan feeder, ezondla izinto ngokulinganayo kwiigranulator ezine ze-extrusion phantsi kwe-feeder ngokusebenzisa i-hopper.Nge-counter-rotating high pressure rollers, izinto eziphathekayo zikhutshwe zibe ngamaqhekeza.Iziqwenga zihamba phantsi ukuya kwigumbi lokutyumza phantsi kwe-roller yokushicilela, apho zichithwa khona ngama-roller atyumkileyo kwaye zihlolwe ukuze zifumane i-granular efunekayo.Iirola zokushicilela zamkela uhlobo olutsha lwentsimbi ekwaziyo ukumelana nokubola, ukunxiba kunye nefuthe.

4. Umatshini wokuHlola weRotary

Ngebhanti yokuhambisa, iigranule ezisuka kwigranulator ye-extrusion zithunyelwa kumatshini wokuhlola ojikelezayo, apho iigranule ezingafanelanga zidlula kwindawo yokuvula isikrini kwaye zikhuphe kwindawo yokuphuma esezantsi, emva koko idluliselwe kwi-pan feeder, ngelixa iigranules ezifanelekileyo ziphumela ngaphandle. indawo yokuphuma kwisiphelo esisezantsi somatshini kwaye idluliselwe kwindawo yokugcina imveliso egqityiweyo.

5. Umatshini wokuPakisha ozenzekelayo

Ngokusetyenziswa kwendawo yokugcina imveliso egqityiweyo, iigranules eziqeqeshiweyo zilinganiswa kwaye zipakishwe ngumatshini wokupakisha ozenzekelayo.Iyunithi ibandakanya ukulinganisa okuzenzekelayo kunye nomatshini wokupakisha, isixhobo sokuhambisa, isixhobo sokutywina kunye nesondlo.Ineempawu zokuchaneka kobunzima obuphezulu, ukusebenza okuzinzileyo, ukusetyenziswa kwamandla aphantsi, kunye nokuhlala kumhlaba omncinci.

Ixesha lokuposa: Sep-27-2020