Yintoni isichumiso esinyibilikayo emanzini?

Isichumisi esinyibilikayo emanzini luhlobo lwesichumisi esisebenza ngokukhawuleza, esibonakaliswa ngokunyibilika kakuhle kwamanzi, sinokunyibilika ngokupheleleyo emanzini ngaphandle kwentsalela, kwaye sinokufunxwa kwaye sisetyenziswe ngokuthe ngqo kwinkqubo yeengcambu kunye namagqabi esityalo.Izinga lokufunxa kunye nokusetyenziswa lingafikelela kwi-95%.Ngoko ke, inokwanelisa iimfuno zesondlo zezityalo ezinesivuno esikhulu kwinqanaba lokukhula ngokukhawuleza.

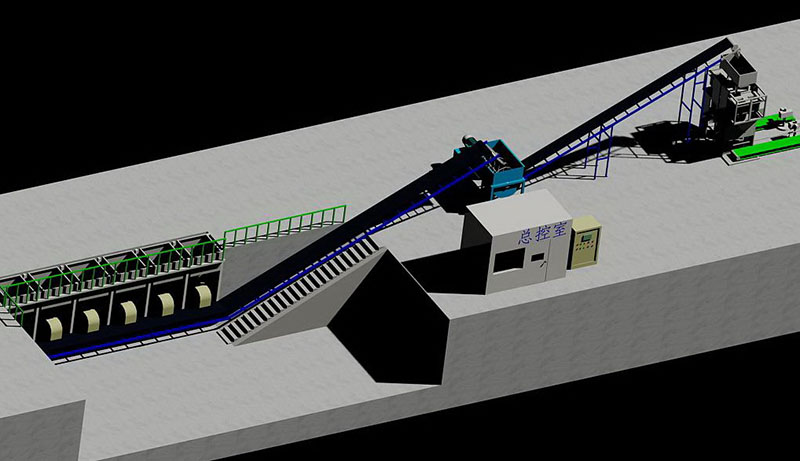

Intshayelelo emfutshane yomgca wokuvelisa isichumiso esinyibilikayo emanzini.

Intshayeleloof Umgca wokuvelisa izichumiso ezinyibilikayo emanzini

Umgca wokuvelisa isichumiso esinyibilikayo ngamanzi sisixhobo esitsha sokwenza isichumiso.Oku kubandakanya ukutya kwezinto eziphathekayo, ukudibanisa, ukuxuba kunye nokupakishwa.Xuba i-1 ~ 5 imathiriyeli ekrwada ngokwefomula yesichumiso, kwaye ke izixhobo zilinganiswa ngokuzenzekelayo, zizaliswe kwaye zipakishwe.

Uluhlu lwethu lwe-Static batching ye-soluble water-soluble line line production izichumiso lunokuvelisa ingxowa ye-10-25kg yeemveliso zesichumiso ezinyibilikayo zamanzi, usebenzisa eyona nkqubo yolawulo lwamazwe ngamazwe, i-sensor yangaphakathi okanye yangaphandle echanekileyo ephezulu, inesakhiwo esihlangeneyo, i-batching echanekileyo, kunye nokuxuba. , ukupakishwa okuchanekileyo.Ikakhulu ifanele imveliso yobuninzi yabenzi bezichumiso ezinyibilikayo zamanzi.

(1) Izixhobo zokulawula iingcali

Inkqubo yokutya ekhethekileyo, isikali se-static batching, ukuxuba okuphakathi, umatshini okhethekileyo wokupakisha wokuzalisa isichumisi esinyibilikayo samanzi, umthumeli weengcali, umatshini wokuthunga ozenzekelayo.

(2) Inkqubo yokuvelisa

Ukutya okungeyomfuneko- Isityumzi sezinto eziphathekayo - Umatshini wokuhlola welinear – Isinyusi sebhakethi – Umsasazi wezinto eziphathekayo - Isithuthi seSpiral - Ibhetshi yekhompyuter engatshintshiyo - Umatshini wokuxuba - Umatshini wokupakisha omninzi

(3) Imilinganiselo yemveliso:

1. Umthamo wokuvelisa: iitoni ezi-5;

2. Izithako: 5 iintlobo;

3. Isixhobo sokudibanisa: i-1 iseti;

4. Umthamo wokudibanisa: iitoni ezi-5 zesichumisi esinyibilikayo ngamanzi ngeyure;

5. Ifom yokudibanisa: i-static batching;

6. Ukuchaneka kwesithako: ± 0.2%;

7. Ifom yokuxuba: Umxube onyanzelweyo;

8. Umthamo wokuxuba: iitoni ezi-5 zokuxuba okuphakathi ngeyure;

9. Ifom yezothutho: ibhanti okanye i-elevator yebhakethi;

10. Uluhlu lokupakisha: 10-25 kg;

11. Umthamo wokupakisha: iitoni ezi-5 ngeyure;

12. Ukuchaneka kokupakishwa: ±0.2%;

13. Ukulungelelaniswa kokusingqongileyo: -10℃ ~ +50℃;

Ukuqaliswa kwezixhobo eziphambili zomgca wokuvelisa izichumisi ezinyibilikayo emanzini

Umgqomo wokugcina: Ukugcinwa kwezinto ezingenayo ukuze zilungiswe

Umgqomo ubekwe ngaphezu komatshini wokupakisha kwaye uxhunywe ngokuthe ngqo kunye ne-flange yomatshini wokupakisha.Ivalve ibekwe ngaphantsi komgqomo wokugcina ukugcinwa okanye ukuvalwa kwangethuba kwesondlo;Udonga lomgqomo wogcino luxhotyiswe ngenqanaba eliphezulu kunye nesezantsi lokumisa ukujikeleza kwinqanaba lokujonga umgangatho wezinto eziphathekayo.Xa izinto ezingenayo zigqithisa i-stop stop spinning level switch, umatshini we-screw feeding ulawulwa ukuyeka ukutyisa.Xa ingaphantsi komgangatho ophantsi wokujikeleza wokujikeleza, umatshini wokupakisha uya kuyeka ukusebenza ngokuzenzekelayo kwaye ukukhanya kombuso kuya kukhanyisa ngokuzenzekelayo.

Inkqubo yokutya isikali sokulinganisa

Olu ngcelele lwenkqubo ye-elektroniki yokutya isikali, yamkela ulawulo loguqulo lwamaza, kukho imowudi enkulu, encinci kunye nekhawulezileyo yokumisa, isantya esikhulu sokupakisha solawulo lokutya, ukuchaneka kokupakishwa kokutya okuncinci.Kwimeko yokupakishwa kwe-25kg, i-5% yokutya okuncinci iyamkelwa xa isondlo esikhulu sifikelela kuma-95%.Ke ngoko, le ndlela yokutya ayinakuqinisekisa kuphela isantya sokupakisha kodwa ikwaqinisekisa ukuchaneka kokupakishwa.

Inkqubo yokulinganisa

Inkqubo yokutya ifakwe ngokuthe ngqo kwingxowa yokupakisha ngokusebenzisa umgqomo wokugcina.Yenziwe kakuhle, inomahluko omncinci wokulahla kunye nokutywinwa okulungileyo.Umzimba womgqomo unqunyanyisiwe kwaye ugxininiswe kwi-sensor (ukusebenza kwenzwa: uvakalelo oluphumayo: inqanaba lokuchaneka kwe-2MV / V: 0.02 ukuphindaphinda: 0.02%; Uluhlu lwembuyekezo yobushushu: -10 ~ 60 ℃; Uluhlu lobushushu obusebenzayo -20 ~ +65 ℃; Kuvunyelwe i-overload : 150%), ukuze ingabinanxibelelwano ngqo nangaphandle ukuze ifezekise ukuchaneka okuphezulu.

Isixhobo sebhegi yokubambelela

I-Adopt anti-slip kunye ne-wear-resisting material, inokwenza ngokwezifiso ububanzi be-entrapment ngokwesikhwama sezinto ezahlukeneyo, kwaye umnyango wokukhupha uya kuvula ngokuzenzekelayo emva kokuba isikhwama esilandelayo sigubungele, kwaye ukutya kuya kuqalisa kwakhona;Yamkela i-bag clamping structure evaliweyo kwaye iqhutywe yi-cylinder, kulula ukuyisebenzisa kwaye kulula ukuyigcina.

Umhambisi

Ukuphakama okuhlengahlengiswayo, isantya esilungelelanisiweyo, sinokujika okanye umva, macala omabini ebhanti kunye nepleyiti yokulinda, inokwenza ukuba isikhwama singaphambuki kwaye siwele;Ubude obuqhelekileyo buyi-3m, kwaye iingxowa zithunyelwa kumatshini wokuthunga.

Umashini wothunga

Ngomsebenzi wokuthunga ozenzekelayo.

Isantya esiphezulu: 1400 RPM;

Ubukhulu bokuthunga ubukhulu: 8mm,

Uluhlu lohlengahlengiso lwe-Stitch: 6.5 ~ 11mm;

Uhlobo lokuthunga lwentambo: ikhonkco eliphindwe kabini;

Iinkcukacha zokuthunga :21s/5;20/3 umgca wePolyester;

Ukuphakamisa ukuphakama kwenyawo locinezela: 11-16mm;

imodeli yenaliti Machine : 80800×250 #;

Amandla: 370 W;

Ngenxa yokuba ukuphakama kwengxowa yokupakisha akuqinisekanga, i-screw lifting mechanism ibekwe kwikholamu, ukuze isetyenziswe kwiingxowa eziphakamileyo ezahlukeneyo;Ikholomu inikwe isihlalo sekhoyili sokubeka ikhoyili;

Inkqubo yokulawula

Ukwamkela inkqubo yokulawula isixhobo sokudibanisa, inkqubo inozinzo oluphezulu kunye nokumelana nokugqwesa okungcono (ukutywinwa);Umsebenzi wokulungisa ukulahla okuzenzekelayo;Umsebenzi wokulandela umkhondo we-zero ozenzekelayo;Ukulinganisa kunye nomsebenzi we-alam ozenzekelayo;Ingaqhutywa ngesandla okanye ngokuzenzekelayo.Ezi ndlela zimbini zinokutshintshwa nangaliphi na ixesha.

Ukuhamba komsebenzi:

Vula iswitshi yamandla kwaye ujonge ukuba isalathisi samandla sivuliwe.Ukuba akunjalo, khangela ukuba amandla adityaniswe kakuhle.

Nokuba amalungu asebenza ngokwesiqhelo phantsi kwemo yesandla;

Seta ifomyula (ifomula inokwenziwa ngokuhambelana nencwadana yokusebenza).

Layita ngokuzenzekelayo.

Umntu omnye uya kubeka isikhwama kwi-othomathikhi entrapment yokuvula, kwaye isikhwama siya kuqala ukuzalisa ngokuzenzekelayo.Emva kokuzaliswa, isikhwama siya kuphumla ngokuzenzekelayo.

Iingxowa eziwayo ziya kuthuthelwa kumatshini wokuthunga ukuze athungwe ngumhambisi.

Yonke inkqubo yokupakisha igqityiwe.

Izinto eziluncedo kumgca wokuvelisa isichumiso esinyibilikayo emanzini:

1. Inkqubo yokudibanisa ithatha amacandelo angundoqo olawulo lwe-static batching;

2. Ngenxa yokungabi namanzi okungahambi kakuhle kwezinto ezisetyenziswayo zamanzi e-soluble, inkqubo yokutya ekhethekileyo yamkelwa ukuze kuqinisekiswe inkqubo yokutya egudileyo yezinto eziluhlaza ngaphandle kokuthintela.

3. Indlela yokulinganisa i-Static yamkelwa kwisikali sokulinganisa ukuqinisekisa ukuba i-batching echanekileyo kunye nexabiso lokudibanisa lisebenza kwiitoni ezi-8 ngeyure;

I-4, Ukusebenzisa i-elevator yebhakethi ekutyeni (izinto ezilungileyo: ukuxhathisa ukubola, ubomi obude, isiphumo esihle sokutywinwa, izinga eliphantsi lokungaphumeleli; Indawo encinci yomgangatho; Yila ngokweemeko zesayithi kunye neemfuno);

5. Isixhobo sokulawula isikali sokupakisha sinokuchaneka ukuya kwi-0.2%.

6. Ngenxa yokubola kwesichumiso esinyibilikayo samanzi, iindawo zoqhagamshelwano zalo mgca wokuvelisa zonke zenziwe ngentsimbi esemgangathweni yesizwe eneepleyiti ezityebileyo, ezomeleleyo kunye nezizinzileyo.

Iingxaki eziqhelekileyo zesichumiso esinyibilikayo samanzi kunye namanyathelo okuthintela

Ukufunxa ukufuma kunye nokudibanisa

Isenzeko sokufunxa ukufuma kunye nokuhlanganiswa kwe-agglomerating kwenzeka emva kokuba imveliso egqityiweyo igcinwe ixesha elithile.

Isizathu: inxulumene ne-hygroscopicity yemathiriyeli ekrwada, isiqulatho samanzi semathiriyeli, ukufuma okunxulumene nendawo yemveliso, kunye nokufunxwa kwamanzi kwizinto zokupakisha.

Isisombululo: Nika ingqalelo ukugcinwa kwezinto eziluhlaza, ukufunyanwa kwangexesha kwezinto ezintsha, kunokusebenzisa i-hydrated magnesium sulfate agglomerating agent.

2. Ukupakishwa kwe-flatulence

Emva kokuba imveliso ibekwe ixesha elithile ehlotyeni, igesi yenziwa kwingxowa yokupakisha, ebangela ukuba ukupakishwa kuqhume okanye kuqhume.

Isizathu: Kudla ngokuba imveliso iqulethe urea, kwaye inxalenye igesi ikakhulu carbon dioxide.

Isisombululo: sebenzisa izinto zokupakisha ezifakwe i-aerated, nikela ingqalelo kwiqondo lokushisa lokugcinwa kweemveliso ezigqityiweyo.

3. Ukonakala kwezinto zokupakisha

Isizathu: Ezinye iifomyula zikholisa ukugqwalisa imathiriyeli yokupakisha.

Isisombululo: Nika ingqalelo ekukhethweni kwezinto zokupakisha, ukukhethwa kwezinto zokupakisha kufuneka kuthathelwe ingqalelo izinto eziluhlaza kunye nefomula.

Ixesha lokuposa: Sep-27-2020