Iukwaziswa koMda weMveliso yeziTyalo eziDityanisiweyo

ICompound Fertilizer sisichumisi esiqulethe izondlo ezimbini okanye ezintathu zeN, P;K. Isichumisi esidibeneyo sifumaneka ngomgubo okanye ifom yegranular.Idla ngokusetyenziswa njengendawo yokugquma phezulu kwaye ingasetyenziswa nanjengomgquba wesiseko kunye nomgquba wembewu.Isichumisi esidibeneyo siqulethe izinto eziphezulu ezisebenzayo, ngoko ke i-soluble ngokulula emanzini, ibola ngokukhawuleza, kwaye ifakwe lula yinkqubo yeengcambu, ngoko ibizwa ngokuba "isichumisi esisebenza ngokukhawuleza".Umsebenzi wayo kukuhlangabezana nemfuno ebanzi kunye nokulungelelanisa izondlo ezahlukeneyo ezifunwa zizityalo phantsi kweemeko ezahlukeneyo.

Lo mgca wemveliso yesichumiso usetyenziswa ikakhulu ukugranula iigranule zesichumiso esixubeneyo usebenzisa izinto zeNPK, GSSP, SSP, granulated potassium sulphate, sulfuric acid, ammonium nitrate, kunye nabanye.Isixhobo se-compound yesichumisi sineengenelo zokuqhuba okuzinzileyo, izinga lokungasebenzi kakuhle, ukugcinwa okuncinci kunye nexabiso eliphantsi.

Umgca wemveliso wonke uxhotyiswe ngezixhobo eziphambili kunye nezisebenzayo, ezinokufikelela kwimveliso yonyaka yeetoni ezingama-50,000 zesichumisi esihlanganisiweyo.Ngokweemfuno zomthamo wemveliso, sicwangcisa kwaye siyila imigca yokuvelisa isichumiso esahlukileyo esinomthamo owahlukileyo wonyaka we-10,000 ~ 300,000 yeetoni.Iseti yonke yezixhobo i-compact, ingqiqo, isayensi, ukusebenza ngokuzinzile, ukonga amandla, ixabiso eliphantsi lokugcinwa, kulula ukusebenza, lolona khetho lungcono kubenzi bezichumisi ezidibeneyo.

Inkqubo yokuvelisa isichumiso esihlanganisiweyo esiphakathi

Inkqubo yokuvelisa umgca we-compound yemveliso yesichumisi ingahlulwa ngokubanzi ibe: ukuxutywa kwezinto eziluhlaza, ukuxuba, ukutyumza, i-granulating, ukuhlolwa okuphambili, ukomiswa kwegranule kunye nokupholisa, ukuhlolwa kwesibini, ukugquma kwegranule kunye nokupakishwa kobuninzi.

1. I-Raw materials batching: ngokwemfuno yemarike kunye neziphumo zokumiselwa komhlaba wendawo, imathiriyeli ekrwada enje ngeurea, ammonium nitrate, ammonium chloride, ammonium sulphate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, heavy calcium, calcium chloride) kunye nepotassium chloride ( potassium sulphate) iya kwabiwa ngokomlinganiselo othile.Izongezo kunye nezinto zokulandelela zilinganiswe ngumlinganiselo webhanti kwaye zilinganiswe kumlinganiselo othile.Ngokomlinganiselo wefomula, zonke izinto eziluhlaza zixutywe ngokulinganayo ngumxube.Le nkqubo ibizwa ngokuba yi-premix.Iqinisekisa ukuqulunqwa okuchanekileyo kwaye yenza ukuba i-batching esebenzayo kunye eqhubekayo.

2. Ukuxuba: Xuba ngokupheleleyo izinto ezilungiselelwe ekrwada kwaye uzishukumise ngokulinganayo, nto leyo ibeka isiseko sesichumiso esisebenzayo nesiphezulu segranular.Umxubi othe tyaba okanye umxube wediski unokusetyenziselwa ukuxuba.

3. Ukutyumza: Ukutyumza i-caking kwizinto eziyimfuneko kwi-processing granulation elandelayo.Ikhonkco lokutyumza lisetyenziswa ikakhulu.

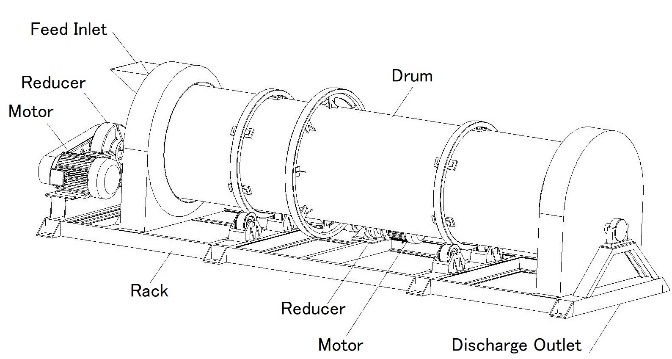

4. I-Granulating: Izinto ezixutywe ngokulinganayo kunye nezichotshoziweyo zihanjiswa kwi-granulator ngokusebenzisa i-belt conveyor ye-granulating, eyona nxalenye ephambili yomgca wokuvelisa wonke.Ukukhethwa kwegranulator kubaluleke kakhulu, sinegranulator yediski, i-rotary drum granulator, i-roller extrusion granulator okanye i-compound yesichumisi segranulator yokuzikhethela.

5. Uvavanyo lokuqala: Thatha uvavanyo lokuqala lweegranules, kwaye ubuyisele abo bangafanelekanga ukuba bacule ukuze baphinde bacocwe.Ngokuqhelekileyo, umatshini wokuhlola ojikelezayo usetyenziswa.

6. Ukomisa: Iigranule ezifanelekayo emva kokuhlolwa kweprayimari zithuthwa ngumqhubi webhanti kwi-rotary dryer ukuze zomiswe ukunciphisa umthamo womswakama ogqityiweyo.Emva kokumisa, umxholo wokufuma we-granules uya kuncipha ukusuka kwi-20% -30% ukuya kwi-2% -5%.

7. Ukupholisa iigranules: Emva kokumisa, iigranules ziya kuthunyelwa kwi-cooler ukuze zipholile, ezidibaniswe nesomisi ngumqhubi webhanti.Ukupholisa kunokususa uthuli, ukuphucula ukusebenza kakuhle kokupholisa kunye nomlinganiselo wokusetyenziswa kobushushu, kunye nokususa ngakumbi ukufuma kwisichumisi.

8. Ukuhlolwa kweSekondari: Emva kokupholisa, zonke iigranules ezingafanelekanga zikhunjulwe ngaphandle ngomatshini wokuhlola ojikelezayo kwaye zithuthwe ngumhambisi webhanti kwi-mixer kwaye zixutywe kunye nezinye izinto eziluhlaza ukuze ziphinde zilungiswe.Iimveliso ezigqityiweyo ziya kuthuthelwa kumatshini wokugquma isichumiso.

9. I-Coating: Isetyenziselwa kakhulu ukugqoka ubuso be-quasi-granules kunye nefilimu yokukhusela efanayo ukuze ukwandise ngokufanelekileyo ixesha lokugcinwa kunye nokwenza i-granules ibe lula.Emva kokugquma, apha yiza kwinkqubo yokugqibela - ukupakisha.

10. Inkqubo yokupakisha: Umatshini wokupakisha wokulinganisa ngokuzenzekelayo wamkelwa kule nkqubo.Umatshini uqulunqwe ngumatshini wokulinganisa kunye nokupakisha, inkqubo yokuhambisa, umatshini wokutywina kunye nokunye.IHopper nayo ingaqwalaselwa ngokweemfuno zabathengi.Ukupakishwa kobuninzi bezinto ezininzi ezifana nesichumisi esiphilayo kunye nesichumisi esihlanganisiweyo sisetyenziswe ngokubanzi kwimizi-mveliso eyahlukeneyo kunye namasimi.

Itekhnoloji kunye neempawu zomgca wokuvelisa isichumiso esihlanganisiweyo:

I-Rotary drum granulator isetyenziswa ikakhulu kwimveliso yetekhnoloji yesichumiso esixutywe kakhulu, idisc non-steam granulator ingasetyenziselwa ukuveliswa koxinzelelo oluphezulu, oluphakathi kunye noluphantsi lwetekhnoloji yesichumisi esidibeneyo, zidityaniswe netekhnoloji ye-anti-caking, i-nitrogen ephezulu. Ubuchwephesha bokuvelisa isichumiso esihlanganisiweyo njalo njalo.Umgca wethu wokuvelisa isichumiso esihlanganisiweyo unezi mpawu zilandelayo:

1. Ukusetyenziswa ngokubanzi kwemathiriyeli ekrwada: izichumisi ezihlanganisiweyo zinokuveliswa ngokweendlela ezahlukeneyo kunye nemilinganiselo, kwaye ifanelekile ukuveliswa kwezichumisi ze-organic kunye ne-inorganic compound.

2. Izinga eliphezulu le-pellet-forming kunye nesantya sokusinda kwebhaktheriya yezinto eziphilayo: iteknoloji entsha inokwenza izinga le-pellet-forming lifikelele kwi-90% ~ 95%, kunye nobushushu obuphantsi kunye ne-high-air drying technology ingenza izinga lokusinda kwiibhaktheriya ezincinci. ukufikelela kwi-90%.Imveliso egqityiweyo ilungile ngokubonakala kunye neyunifomu ngobukhulu, i-90% yayo i-granules kunye nobukhulu be-2 ~ 4mm.

3. Ukuhamba kwenkqubo eguquguqukayo: Ukuhamba kwenkqubo yomgca wokuvelisa isichumisi esihlanganisiweyo kunokulungelelaniswa ngokwezona zinto zikhoyo, ifomula kunye nesayithi, kunye nokuhamba kwenkqubo elungiselelweyo kunokuthi kuyilwe ngokweemfuno zokwenene.

4. Umlinganiselo wezondlo ozinzileyo weemveliso ezigqityiweyo: ngokulinganisa okuzenzekelayo kwezithako, ukulinganisa okuchanekileyo kwazo zonke iintlobo zezinto eziqinileyo, ulwelo kunye nezinye izinto eziluhlaza, phantse zigcine uzinzo kunye nokusebenza kwazo zonke izondlo kwinkqubo yonke.

CImveliso ye-ompound yezichumiso LmnaUsetyenziso

1.Sulphur camera inkqubo yokuvelisa urea.

2.Uhlobo olwahlukileyo lwenkqubo yesichumiso esiphilayo kunye ne-inorganic.

3.Inkqubo yokuxutywa kwesichumiso esixutywe ne-Acid.

4.Inkunkuma yemveliso yePowdery inkqubo yesichumiso.

5.Inkqubo yokuvelisa i-particle urea enkulu.

6.Inkqubo yokuvelisa isichumiso seSeedling Substrate.

Ixesha lokuposa: Sep-27-2020