Okokuqala, makhe sijonge kwizinto ezisetyenziswayo xa kusenziwa isichumiso esixutywe nenye:

1) Isichumisi se-nitrogen: i-ammonium chloride, i-ammonium sulfate, i-ammonium sulfide, i-urea, i-calcium nitrate, njl.

2) Isichumiso sePotassium: potassium sulfate, ingca ash, njl.

3) Isichumiso sephosphate: superphosphate, superphosphate enzima, calcium magnesium phosphate fertilizer, phosphate powder, njl.

20,000 Tons/Unyaka Iintshayelelo zoMda weMveliso yesichumiso esiDityanisiweyo:

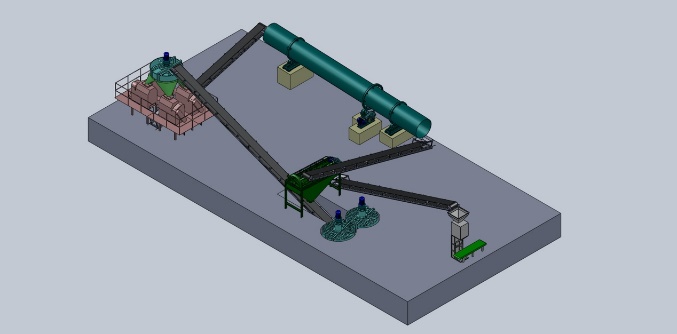

Le 20,I-000 t/y umgca wokuvelisa isichumiso esidityanisiweyo yindibaniselwano yothotho lwezixhobo eziphambili.Ibonakaliswa ngeendleko eziphantsi zemveliso kunye nokusebenza kakuhle kwemveliso.Lo mgca wemveliso ungasetyenziselwa ukugranula zonke iintlobo zemathiriyeli ekrwada ekrwada.Kwaye iinqununu zokugqibela zesichumisi zingenziwa ngogxininiso oluhlukeneyo ngokweemfuno zangempela, ezinokuncedisa ngokufanelekileyo izondlo eziyimfuneko kwizityalo kunye nokusombulula iingxabano phakathi kweemfuno zezityalo kunye nokunikezelwa komhlaba.

Ngokuqhelekileyo, umgca wokuvelisa isichumisi odibeneyo udla ngokuquka ezi ndawo zilandelayo: inkqubo yokuxuba, inkqubo ye-granulating, inkqubo yokomisa, inkqubo yokupholisa, inkqubo yokuhlola, inkqubo yokugubungela kunye nenkqubo yokupakisha.

20,000 t/y isichumiso esihlanganisiweyo seGranulation Production Line Main Amacandelo:

1.Dynamic batching machine

Umatshini wokudibanisa uxhotyiswe ngamabhonki amathathu okanye ngaphezulu, anokongezwa okanye ancitshiswe ngokweemfuno zabathengi.Ukuphuma komgqomo ngamnye kuxhotyiswe ngeengcango ze-elektroniki ze-pneumatic, kwaye umzantsi womgqomo une-hopper yobunzima, kwaye umzantsi we-hopper udityaniswe nesixhobo sokuhambisa ibhanti.I-hopper kunye ne-belt conveyor imisiwe kwelinye icala le-lever yokuqhuba, kwaye enye isiphelo se-lever idibaniswe ne-sensor ye-tension, kwaye i-sensor kunye ne-pneumatic control part idibaniswe nekhompyutheni.Umatshini wamkela umatshini wokulinganisa we-elektroniki, olawulwa ngokuzenzekelayo ngumlawuli we-batching ukugqiba umlinganiselo wokulinganisa wezinto nganye ngokulandelelana.Ineenzuzo zesakhiwo esilula, ukuchaneka okuphezulu kwe-batching kunye nokusebenza okulula.

2.Isityuli seChayini esithe nkqo:

Hlanganisa iimathiriyeli ezikhompawundi ezahlukeneyo ngokomlinganiselo othile, uze uzibeke kwi-Vertical Chain Crusher.Izinto eziluhlaza ziya kutyunyuzwa zibe ngamaqhekeza amancinci ukuze zikwazi ukuhlangabezana neemfuno zenkqubo yegranulating.

3.Disic Mixer:

Emva kokuba izinto eziluhlaza zityunyuziwe, ziya kuthunyelwa kwi-Disc Mixer, apho izinto eziluhlaza ziya kuhlanganiswa ngokufanayo.Ilayini ye-pan yenziwe nge-polypropylene okanye ngeshiti lentsimbi, ngoko ke izinto ezonakalisayo ezine-viscosity ephezulu akulula ukunamathela, nto leyo enceda ukuphucula ukusebenza kakuhle kunye nomgangatho wemveliso.Emva koko izinto ezixubileyo ziya kuthunyelwa kwi-Rotary Drum Granulator.

4.IiRollers extrusion granulation:

Ukusebenzisa iteknoloji ye-extrusion eyomileyo, akukho nkqubo yokumisa ifunekayo.Ubukhulu becala luxinzelelo lwangaphandle, izinto ezinyanzeliswayo ngokucocwa phakathi kweerola ezijikelezayo ezimbini, kwaye zicinezelwe zibe ziingceba.Ubuninzi bokwenene bezinto eziphathekayo bunokunyuswa ngamaxesha angama-1.5-3 ukufikelela kumlinganiselo othile wamandla.Uxinzelelo lwe-extrusion lunokulungiswa ngenkqubo ye-hydraulic.Lo matshini uneenzuzo zokuguquguquka okukhulu kokusebenza kunye nobubanzi bokusebenzisa uluhlu.Ayisiyosayensi kuphela kwaye isengqiqweni kulwakhiwo, kodwa kunye notyalo-mali oluncinci, isiphumo esikhawulezayo kunye nenzuzo entle kwezoqoqosho.

5.I-Rotary Drum Screening machine:

Emva kokungena kumatshini wokuhlola umgqomo we-rotary, iinqununu ezifanelekileyo ziya kuthunyelwa kumatshini wokugubungela, ngelixa iinqununu ezingafanelekanga ziya kukhethwa kwaye zithunyelwe kwi-Vertical Chain Crusher ukuze zihlanjululwe kwakhona.Lo matshini wamkela isikrini sendibano, esilungele ukulungiswa kunye nokutshintshwa.Ulwakhiwo lulula, ukusebenza kukulungele, kwaye ukuqhuba kuzinzile.Sisixhobo esiyimfuneko kumgca wokuvelisa isichumiso.

6.Umatshini wokugquma wezichumiso ezijikelezayo:

Amasuntswana afanelekileyo aya kugqunywa ngumatshini wokugquma ojikelezayo, oza kuhombisa amasuntswana kwaye womeleze ubulukhuni babo ngaxeshanye.Umatshini wokugquma ojikelezayo wamkela itekhnoloji yolwelo olukhethekileyo lokutshiza kunye netekhnoloji eqinileyo yokugquma i-powder ukunqanda i-caking yamasuntswana ezichumisi ngokufanelekileyo.

7.Umatshini wokuPakisha izichumisi:

Emva kokuba iinqununu zifakwe, ziya kufakwa ngumatshini wokupakisha.Umatshini wokupakisha unomgangatho ophezulu wokuzenzekelayo, odibanisa ubunzima, ukuthunga, ukupakisha kunye nokuhambisa, ukuqonda ngokukhawuleza ukupakishwa kobuninzi ukwenza inkqubo yokupakisha isebenze ngakumbi kwaye ichanekile.

8.Belt Conveyors:

Abahambisi badlala indima ebaluleke kakhulu kwinkqubo yokuvelisa, kuba idibanisa iindawo ezahlukeneyo zomgca wemveliso.Kulo mgca wokuvelisa isichumiso esihlanganisiweyo, sikhetha ukukunika abahambisi bebhanti.Xa kuthelekiswa nezinye iintlobo zokuthutha, i-conveyor yebhanti ine-coverage enkulu, eya kwenza inkqubo yakho yokuvelisa isebenze ngakumbi kwaye iqoqosho.

Izinto ezilungileyo ze20,000 Tons/Unyaka weNxibelelaniso yeMveliso yezichumiso:

I-1.Lo mgca wemveliso yesichumisi esihlanganisiweyo ubonakaliswe ngokusetyenziswa okuphantsi, umthamo ophezulu wemveliso kunye nokuzuza okulungileyo kwezoqoqosho.

I-2.Umgca wokuvelisa wamkela iteknoloji ye-granulation eyomileyo, edlula inkqubo yokomisa kunye nokupholisa kwaye inciphisa kakhulu iindleko.

I-3.Eyilwe kunye nezakhiwo ezidibeneyo kunye nengqiqo, umgca wokuvelisa isichumisi esidibeneyo uya kuba nomthamo omkhulu wokusebenza, onokufaneleka ngakumbi kwiimfuno zemveliso yesichumisi esidibeneyo ngoku.

4.Ngexesha lenkqubo yokuvelisa, amandla amancinci asetyenziswa kwaye akukho nkunkuma emithathu eyenziwayo.Lo mgca wemveliso yesichumisi esidityanisiweyo unomsebenzi ozinzileyo kunye nomgangatho othembekileyo owandisa ubomi obude benkonzo.

5.Lo mgca wokuvelisa isichumiso esihlanganisiweyo ungasetyenziswa ekuveliseni zonke iintlobo zezinto ezikrwada ekrwada.Kwaye izinga legranulation liphezulu ngokwaneleyo.

I-6.Lo mgca wokuvelisa isichumisi odibeneyo ungasetyenziselwa ukuvelisa isichumisi esixubileyo kunye noxinzelelo oluhlukeneyo, olunokuthi luhlangabezane neemfuno zabathengi abahlukeneyo.

Ixesha lokuposa: Sep-27-2020