Umatshini wokupholisa weGuru leRotary

IUmatshini wokupholisa iiPellets zezichumisoyenzelwe ukunciphisa ungcoliseko lomoya obandayo kunye nokuphucula indawo yokusebenza.Ukusetyenziswa komatshini wokupholisa amagubu kukwenza mfutshane inkqubo yokwenziwa kwezichumiso.Ukuhambelana nomatshini wokomisa kunokuphucula kakhulu izinga lokupholisa, kungekhona nje ukunciphisa amandla omsebenzi, kodwa kwakhona ukususa umswakama kunye nokunciphisa ubushushu beegranules zesichumisi.Iumatshini opholileyo ojikelezayoingasetyenziselwa ukupholisa ezinye izinto ezinomgubo kunye negranular.Isixhobo sinesakhiwo esincinci, ukusebenza kakuhle kokupholisa, ukusebenza okuthembekileyo kunye nokulungelelanisa okunamandla.

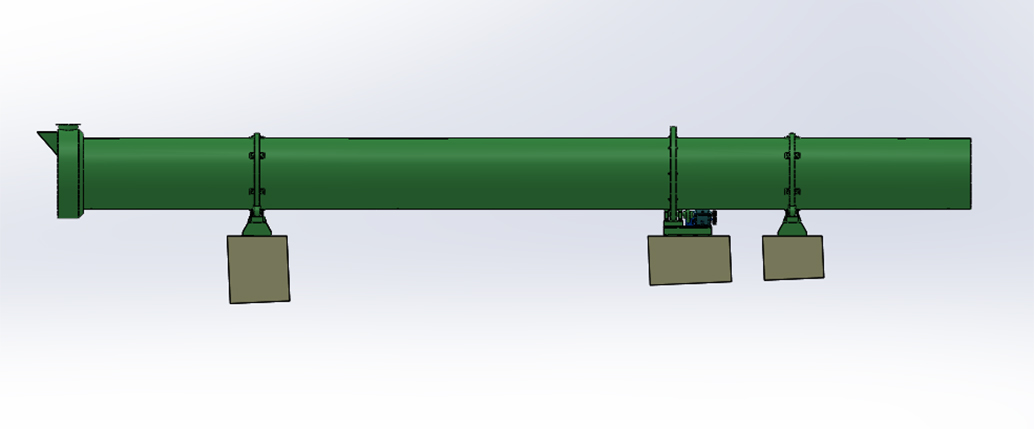

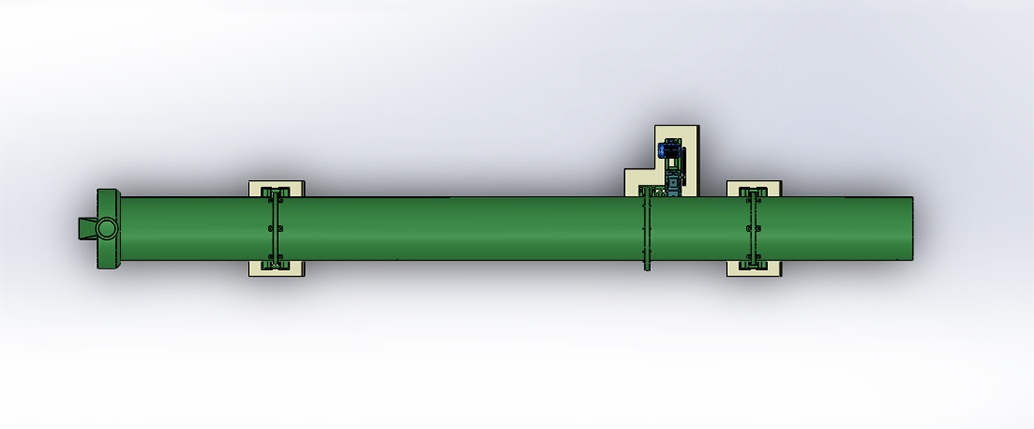

Umatshini wokupholisa iiPellets zezichumisoyamkela indlela yokutshintshiselana ngokufudumeza kwizinto ezipholileyo.Ixhotyiswe ngentsimbi edityanisiweyo yamaphiko e-scraping phambi kombhobho kunye nepleyiti yokuphakamisa ekupheleni kwe-cylinder, kunye nenkqubo yokuncedisa ipayipi kufuneka ifakwe kunye nomatshini wokupholisa.Njengoko i-cylinder ijikeleza ngokuqhubekayo, ipleyiti yokuphakamisa yangaphakathi iphakamisa ngokuqhubekayo i-granules yesichumisi phezulu nangaphantsi ukuze idibanise ngokupheleleyo nomoya obandayo wokutshintsha ubushushu.Isichumisi segranular siya kuthotywa ukuya kuma-40°C ngaphambi kokuba sikhutshwe.

1.Isilinda yeUmatshini wokupholisa iiPellets zezichumisoyityhubhu ejiyileyo eyi-14mm engqingqwa edibeneyo, enezibonelelo zokugxila okuphezulu kunye nokusebenza okuzinzileyo kwentsimbi.Ubunzima beplate yokuphakamisa yi-5mm.

2. Isixhobo se-ring, i-roller belt idler kunye nesibiyeli zonke zi-castings zentsimbi.

3. Khetha iiparamitha ezifanelekileyo zokusebenza ukulungelelanisa "isondlo kunye nomoya", ngaloo ndlela uphucula kakhulu ukutshintshiselana ngokufanelekileyoUmatshini wokupholisa iiPellets zezichumisokunye nokunciphisa ukusetyenziswa kwamandla ngama-30-50%.

4. I-cylinder ithatha ityhubhu ejikelezayo, kwaye umzi-mveliso wentsimbi usebenzisa ngokuthe ngqo ipleyiti efanayo ukuze udibanise kwi-bobbin ukuthintela ukonakala kwinqanaba lamva;uthutho olufanelekileyo lwahlulwe lwaba ngamacandelo amabini, kwaye uxhulumaniso lwe-flange oluphakathi kunye negolide lokuzinciphisa liqinisekisa ukudibanisa okuqinileyo.

Kukho iintlobo ezininziUmatshini wokupholisa iiPellets zezichumiso, enokuthi ikhethwe ngokweemfuno zokwenyani, okanye ilungiselelwe.Iiparamitha eziphambili zobugcisa zibonisiwe kolu luhlu lulandelayo:

| Umzekelo | Ububanzi (mm) | Ubude (mm) | Imilinganiselo (mm) | Isantya (r/min) | Imoto

| Amandla (kw) |

| YZLQ-0880 | 800 | 8000 | 9000×1700×2400 | 6 | I-Y132S-4 | 5.5 |

| YZLQ-10100 | 1000 | 10000 | 11000×1600×2700 | 5 | Y132M-4 | 7.5 |

| YZLQ-12120 | 1200 | 12000 | 13000×2900×3000 | 4.5 | Y132M-4 | 7.5 |

| YZLQ-15150 | 1500 | 15000 | 16500×3400×3500 | 4.5 | Y160L-4 | 15 |

| YZLQ-18180 | 1800 | 18000 | 19600×3300×4000 | 4.5 | Y225M-6 | 30 |

| YZLQ-20200 | 2000 | 20000 | 21600×3650×4400 | 4.3 | Y250M-6 | 37 |

| YZLQ-22220 | 2200 | 22000 | 23800×3800×4800 | 4 | Y250M-6 | 37 |

| YZLQ-24240 | 2400 | 24000 | 26000×4000×5200 | 4 | Y280S-6 | 45 |