Enye yeenzuzo ezinkulu ekusebenzeni noYi Zheng lulwazi lwethu olupheleleyo lwenkqubo;asizizo iingcaphephe kwinxalenye enye yenkqubo, kodwa noko, onke amacandelo.Oku kusivumela ukuba sinikeze abathengi bethu imbono ekhethekileyo malunga nokuba inxalenye nganye yenkqubo iya kusebenza njani kunye xa iyonke.

Sinokubonelela ngeenkqubo ezipheleleyo zegranulation, okanye iziqwenga zezixhobo zomntu ngamnye kuzo zombini usetyenziso lwe-inorganic kunye ne-organic.

Umgca wethu wokuvelisa i-disc granulator ikakhulu uvelisa isichumiso esihlanganisiweyo.Ngokuqhelekileyo, isichumisi esidibeneyo siqulethe ubuncinane izinto ezi-2 zezondlo ezintathu (i-nitrogen, i-phosphorus, kunye ne-potassium).Ngeempawu zomxholo wezondlo eziphezulu, iziphumo ebezingalindelekanga ezimbalwa, kunye neempawu ezintle zomzimba, isichumisi esihlanganisiweyo sidlala indima ebalulekileyo ekulinganiseni ukuchumisa, ukuphucula ukusebenza kakuhle kokufakwa kwesichumiso kunye nokukhuthaza isivuno esikhulu nesizinzileyo sezityalo, umgca wethu wokuvelisa isichumiso kwi-pan granulator yenzelwe ngokukodwa. abavelisi bezichumiso abanemfuno enkulu yemveliso.Lo mgca wemveliso yesichumiso unokuvelisa isichumiso se-NPK, iDAP kunye negranulate ezinye izinto zibe ngamasuntswana esichumiso.Itekhnoloji yenkqubo yesi sityalo sezichumisi ihambele phambili, iyasebenza kwaye iyasebenza.Zonke izixhobo zesichumisi zixinene, zisebenza ngokuzenzekela kakhulu kwaye zisebenza lula, nto leyo ilungele ukuveliswa kwesichumisi esixandileyo.

I-advanteji:

1.Bonke oomatshini bezichumisi bamkela umhlwa kunye nezixhobo zokungagugi.

2. Umthamo ohlengahlengiswayo ngokweemfuno zomthengi.

3. Akukho nkunkuma ekhutshwayo, ukonga amandla kunye nokunciphisa ukusetyenziswa, ukukhusela okusingqongileyo.Ukusebenza okuzinzileyo, kulula ukuyigcina.

4. Lo mgca wemveliso yesichumiso unokuvelisa kuphela isichumisi esihlangeneyo kunye noxinzelelo oluphezulu, oluphakathi, kunye noluphantsi, kodwa isichumisi esiphilayo, isichumisi se-inorganic, isichumisi se-bio kunye nesichumisi semagnetizing njl. I-Disc granulator enezinga eliphezulu le-granulation.

5. Ngokwakheka okuhlangeneyo, iseti epheleleyo yomgca wokuvelisa isichumiso yinzululwazi kwaye isengqiqweni, kwaye ihambele phambili kwezobuchwepheshe.

7. Ukuguquguquka okubanzi kwezinto eziluhlaza, ezifanelekileyo kwi-granulation yezichumisi ezixubileyo, amayeza, iikhemikhali, ukutya kunye nezinye izinto eziluhlaza.

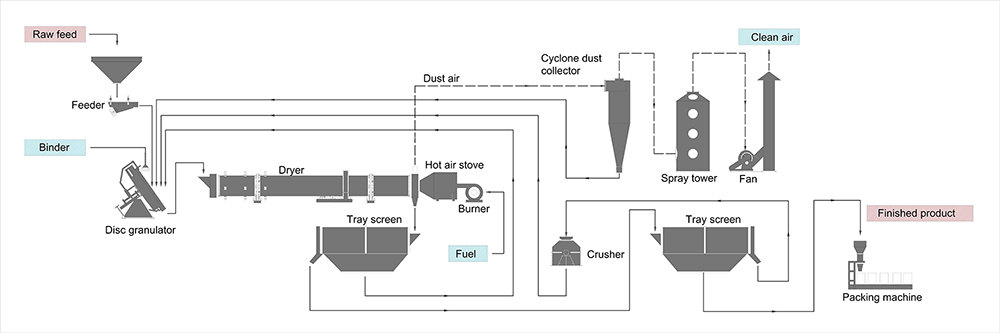

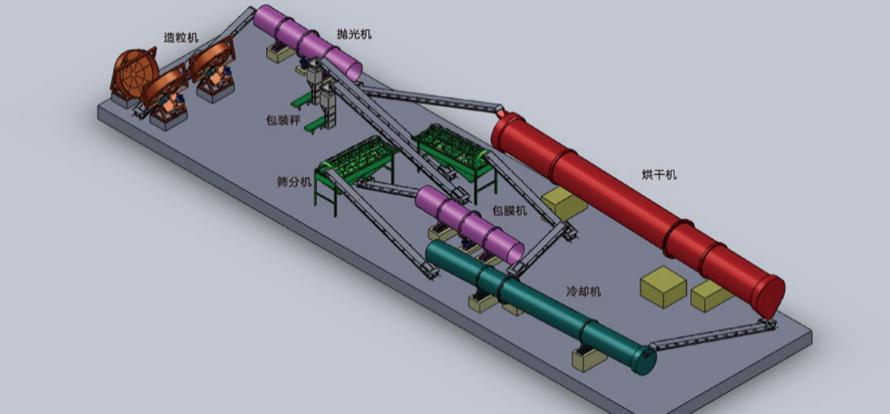

Umgca wonke uquka iDisc feeder (ukubeka imathiriyeli etankini) → Isixhumi sediskhi (sokuvuselela imathiriyeli ekrwada)→ isityuli setsheyini (sokutyumza)→ Isihluzi sediskhi (sokugranula)→ isisomisi sedrum esijikelezayo(sokomisa) → isicolisi segubu esijikelezayo (yokupholisa) → igubu lesikrini esijikelezayo (sokuhlola iimveliso ezigqityiweyo nezingafanelekanga)→ ugcino lweemveliso ezigqityiweyo (zogcino)→umpakisheli ozenzekelayo (wokupakishwa)→ isihambisi sebhanti→igumbi lokumisa uthuli→umtshintshisi wobushushu

ISAZISO:Lo mgca wemveliso ubhekiselele kwireferensi yakho kuphela.

Inkqubo yetekhnoloji yegranulation yomgca wokuvelisa isichumiso esidityanisiweyo inokwahlulwa ngokwesiqhelo ibe:

1.Inkqubo yokuBambisa izinto eziphathekayo

Okokuqala, izinto eziluhlaza zabiwa ngokuhambelana ngokungqongqo nomlinganiselo.Iimathiriyeli ekrwada ziquka urea, ammonium nitrate, ammonium chloride, ammonium sulphate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, superphosphate eyodwa, kunye whiting erhabaxa), potassium chloride, potassium sulfate kunye njl. ukusebenza kakuhle kwezichumiso.

2.Inkqubo yokuXhasa izinto eziphathekayo

Iimathiriyeli ekrwada zixutywe kunye kwidiskhi mixer enokuthi ishukumise imathiriyeli ngokulinganayo.

3.Inkqubo yokutyumza

Umatshini wokutyumza ikhonkco uya kutyumza izinto ezinkulu zibe ngamaqhekeza amancinci anokufikelela kwiimfuno zegranulation.Emva koko i-conveyor yebhanti iya kuthumela izinto kwi-pan granulator kwi-granulate.

4.Inkqubo yeGranulating

Idiskhi yesichumiso segranulator yamkela i-arc disc ye-angle isakhiwo.Izinga le-granulation lingafikelela ngaphezulu kwe-93%, eneyona ndlela ilungileyo ye-granulation ratios phakathi kwazo zonke iigranulator zesichumiso.Ukusebenzisa i-counter-rotation eqhubekayo yesixhobo kunye nesixhobo sokutshiza ukuqhuba imathiriyeli ekrwada eqengqelekayo kwidiski.Inokuvelisa iigranules ezifanayo kunye nembonakalo entle.I-pan granulator ngumatshini oyimfuneko kumgca wokuvelisa isichumiso esihlanganisiweyo.

5.Ukomisa kunye neNkqubo yokuPholisa

Emva kwe-granulating, i-granules kufuneka yomiswe.Umhambisi webhanti uthutha iigranuli ukuya kwisitshisi esijikelezayo segubu.Umatshini wokumisa ususa umswakama kwiinqununu ukwandisa ubuninzi beegranules.Ngaloo ndlela, ikulungele ukugcinwa.Emva kokumisa, ubushushu be-granules buphezulu, kulula ukuba i-agglomerate.Ngaloo ndlela kufuneka sipholise iigranules ngomatshini wokupholisa igubu elijikelezayo.Emva kokuba zipholile, iigranuli zesichumiso kulula ukupakishwa, ukugcinwa kunye nokuthutha.

6.Inkqubo yoHlelo lweNqanaba

Isichumiso kufuneka sihlolwe ngumatshini ojikelezayo wokuhlola igubu emva kokuba sipholisiwe.Iimveliso ezifanelekileyo ziya kuthunyelwa kwindawo yokugcina imveliso egqityiweyo ngokuhambisa ibhanti okanye inokupakishwa ngokuthe ngqo.Iigranuli ezingafanelekanga ziya kuhlanjululwa kwakhona.

7.INkqubo yokuPakisha iMveliso

Ukupakisha yinkqubo yokugqibela kumgca wokuvelisa isichumiso esihlanganisiweyo.Ipakethe yesichumiso esizihambelayo isetyenziselwa ukupakisha iimveliso ezigqityiweyo.Ngokusebenza okuphezulu okuzenzekelayo kunye nokusebenza okuphezulu, ayiphumeleli kuphela ukulinganisa okuchanekileyo, kodwa ifezekisa inkqubo yokugqibela yobuchule ngokugqwesileyo.Abathengi banokulawula isantya sokutya kwaye babeke ipharamitha yesantya ngokweemfuno zangempela.

Ixesha lokuposa: Sep-28-2020