Enye yeenzuzo ezinkulu ekusebenzeni noYi Zheng lulwazi lwethu olupheleleyo lwenkqubo;asizizo iingcaphephe kwinxalenye enye yenkqubo, kodwa noko, onke amacandelo.Oku kusivumela ukuba sinikeze abathengi bethu imbono ekhethekileyo malunga nokuba inxalenye nganye yenkqubo iya kusebenza njani kunye xa iyonke.

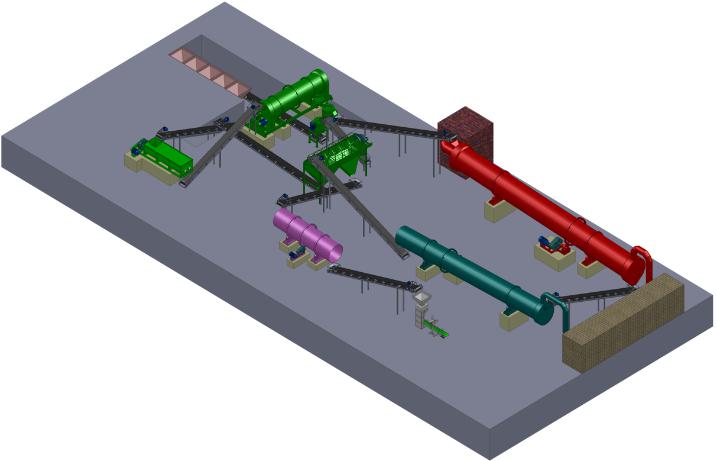

Sinokubonelela ngoyilo lwenkqubo kunye nokubonelela ngomgca wokuvelisa i-rotary drum granulation.

Lo mgca wemveliso we-Rotary Drum Granulation uxhotyiswe ngomatshini we-static batching, i-double-shaft mixer, i-rotary drum granulator, i-chain crusher, i-rotary drum dryer & cooler, i-rotary idrum screening machine kunye nezinye izixhobo zesichumiso ezincedisayo.Imveliso yonyaka ingaba yi-30,000 yeetoni.Njengomvelisi womgca wokuvelisa isichumisi oqeqeshiweyo, sikwabonelela abathengi ngeminye imigca yegranulation enomthamo ohlukeneyo wokuvelisa, onje nge-20,000 T/Y, 50,000T/Y, kunye ne-100,000T/Y, njl.

I-advanteji:

1. I-Adopts advanced rotary drum granulator, ireyithi yegranulation inokufikelela kuma-70%.

2. Amacandelo aphambili athatha izinto zokunxiba kunye ne-corrosion-resistant, izixhobo zinobomi obude benkonzo.

3. Yamkela ipleyiti yeplastiki okanye i-stainless steel plate lining, izinto ezingelula ukunamathela eludongeni lwangaphakathi lomatshini.

4. Ukusebenza okuzinzileyo, ukugcinwa lula, ukusebenza kakuhle, ukusetyenziswa kwamandla aphantsi.

5. I-Adopt ibhanti yokuhambisa ukudibanisa umgca wonke, ukuqonda imveliso eqhubekayo.

6. Yamkela iiseti ezimbini zegumbi lokuhlalisa uthuli ukujongana nerhasi yomsila, enobuhlobo nokusingqongileyo.

7. Amaxesha amabini enkqubo yokuhlola iqinisekisa iigranules ezifanelekileyo ezinobungakanani obufanayo.

8. Ukudibanisa ngokulinganayo, ukomisa, ukupholisa, kunye nokugquma, imveliso egqityiweyo inomgangatho ophezulu.

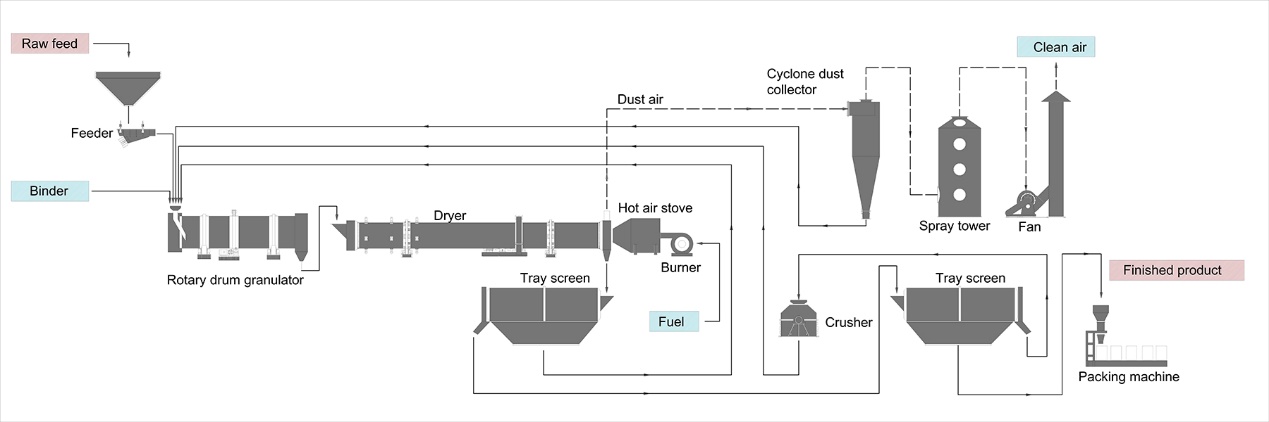

Inkqubo yokuhamba:

Ukuxutywa kwemathiriyeli ekrwada (Umatshini wokubethela omileyo)→Ukuxuba (Umxube weshafti ephindwe kabini)→ Ukugranula (umatshini wokuhluza igubu elijikelezayo) → Ukomisa (isisomisi segubu esijikelezayo) → Ukupholisa (ukupholisa kwegubu elijikelezayo) → Ukuhlolwa kweemveliso ezigqityiweyo (umatshini wokuhluza igubu elijikelezayo) → Umgangatho ophantsi ukutyumza iigranules (isityuli setyathanga lesichumiso esithe nkqo) → Ukwaleka (umatshini wokugquma wegubu) → Iimveliso ezigqityiweyo zipakishwa (ipakethe yobungakanani obuzenzekelayo) → Ukugcinwa (ukugcina kwindawo epholileyo neyomileyo)

ISAZISO:Lo mgca wemveliso ubhekiselele kwireferensi yakho kuphela.

1.I-Raw materials batching

Ngokwemfuno yemarike kunye neziphumo zokumiselwa komhlaba wendawo, imathiriyeli ekrwada enje ngeurea, ammonium nitrate, ammonium chloride, ammonium sulphate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, heavy calcium, calcium general) kunye nepotassium chloride (potassium sulphate) ziyakwabiwa. ngokomlinganiselo othile.Izongezo kunye nezinto zokulandelela zilinganiswe ngumlinganiselo webhanti kwaye zilinganiswe kumlinganiselo othile.Ngokomlinganiselo wefomula, zonke izinto eziluhlaza zixutywe ngokulinganayo ngumxube.Le nkqubo ibizwa ngokuba yi-premix.Iqinisekisa ukuqulunqwa okuchanekileyo kwaye yenza ukuba i-batching esebenzayo kunye eqhubekayo.

2.Ukuxuba

Hlanganisa ngokupheleleyo izinto ezilungisiweyo ezilungisiweyo kwaye uzigxothe ngokulinganayo, ezibeka isiseko sochumisi oluphezulu kunye nomgangatho ophezulu we-granular.Umxubi othe tyaba okanye umxube wediski unokusetyenziselwa ukuxuba.

3.IiMathiriyeli Granulating

Emva kokutyunyuzwa, izinto zihanjiswa kwi-rotary drum granulator ngokuhambisa ibhanti.Ngokujikeleza rhoqo kwegubhu, izinto zenza ibhedi ejikelezayo, kwaye ihamba ngendlela ethile.Phantsi kwamandla extrusion eveliswayo, izinto agglomerate zibe ngamasuntswana amancinane, abe core, encamathisela umgubo ngeenxa ukwenza iigranules abaqeqeshiweyo spherical.

4.Ukomisa izichumiso

Impahla iya komiswa emva kokugalelwa ukuze ifikelele kumgangatho wesiqulatho samanzi.Xa i-dryer ijikeleza, uluhlu lwamaphiko angaphakathi luya kuphakamisa izinto ngokufaka udonga lwangaphakathi lwesomisi.Xa imathiriyeli ifikelela kubude obuthile ukuqengqeleka amaphiko ngasemva, iya kuwiswa ngasemva kwi-dryer, emva koko idlule kumjelo werhasi eshushu njengoko isiwa.Inkqubo ezimeleyo yokuthiya umoya, ukubeka kwindawo enye ukulahlwa kwenkunkuma kumandla kunye nokongiwa kweendleko.

5.Ukupholisa izichumiso

I-cooler ye-Rotary drum isusa amanzi ezichumisi kwaye ithobe ubushushu, isetyenziswe ngesomisi esijikelezayo kwisichumisi esiphilayo kunye nemveliso ye-organic fertilizer, eyandisa kakhulu isantya sokupholisa, kwaye ikhulula ukuqina komsebenzi.Isixhobo esipholileyo esijikelezayo sinokusetyenziselwa ukupholisa ezinye izinto ezinomgubo kunye negranular.

6.Ukuhlolwa kwezichumiso: Emva kokupholisa, zonke iigranules ezingafanelekanga zikhutshelwa ngaphandle ngomatshini wokuhlola ojikelezayo kwaye zithuthwe ngumthuthi webhanti kumxube kwaye zixutywe kunye nezinye izinto eziluhlaza ukuze ziphinde zilungiswe.Iimveliso ezigqityiweyo ziya kuthuthelwa kumatshini wokugquma isichumiso.

7. I-Coating: Isetyenziselwa kakhulu ukugubungela umphezulu we-quasi-granules kunye nefilimu yokukhusela efanayo ukuze ukwandise ngokufanelekileyo ixesha lokulondoloza kunye nokwenza i-granules ibe lula.Emva kokugquma, apha yiza kwinkqubo yokugqibela - ukupakisha.

8. Inkqubo yokupakisha: Umatshini wokupakisha wokulinganisa ngokuzenzekelayo wamkelwa kule nkqubo.Umatshini uqulunqwe ngumatshini wokulinganisa ngokuzenzekelayo kunye nokupakisha, inkqubo yokuhambisa, umatshini wokutywina kunye nokunye.IHopper nayo ingaqwalaselwa ngokweemfuno zabathengi.Ukupakishwa kobuninzi bezinto ezininzi ezifana nesichumisi esiphilayo kunye nesichumisi esihlanganisiweyo sisetyenziswe ngokubanzi kwimizi-mveliso eyahlukeneyo kunye namasimi.

Ixesha lokuposa: Sep-27-2020