Inkqubo yemveliso yomgca wedisk granulation epheleleyo kunye neyohlukeneyo yenye yeenzuzo eziphambili zeHenan Zheng Heavy Industries.Inokubonelela ngezisombululo ezipheleleyo nezithembekileyo zomgca wokuvelisa ngokweemfuno zabathengi.

Sinamava kucwangciso kunye nenkonzo yemigca eyahlukeneyo yokuvelisa izichumiso.Asigxininisi kuphela kuyo yonke ikhonkco yenkqubo kwinkqubo yokuvelisa, kodwa sihlala sibamba iinkcukacha zenkqubo nganye kuwo wonke umgca wemveliso kwaye sifezekise ngempumelelo ukudibanisa.

Umgca wemveliso we-disk granulator usetyenziswa ikakhulu ukuvelisa isichumisi esiphilayo.Isichumisi sendalo singenziwa ngemfuyo kunye nomgquba weenkukhu, inkunkuma yezolimo kunye nenkunkuma eqinileyo kamasipala.Le nkunkuma yendalo kufuneka iqwalaselwe ngakumbi phambi kokuba iguqulwe ibe zizichumisi zentengiso zexabiso lentengiso ezithengiswayo.Utyalo-mali ekuguquleni inkunkuma ibe bubutyebi lunexabiso.

Umgca wokuvelisa isichumiso seDisc granulated organic ufanelekile:

- ►Ukwenziwa kobulongwe benkomo yenkomo yesichumiso esiphilayo

- ►Ukwenziwa komgquba wehagu ophilayo

- ►Ukwenziwa kwezichumiso zenkukhu kunye namadada

- ►Umgquba weegusha ukwenziwa kwezichumiso eziphilayo

- ►Ukwenziwa kwezichumiso zendalo kudaka lwasezidolophini

1. umgquba wezilwanyana: umgquba wenkukhu, umgquba wehagu, umgquba weegusha, umgquba wenkomo, umgquba wamahashe, umgquba wemivundla, njl.

2. inkunkuma yamashishini: iidiliya, i-vinegar slag, i-cassava intsalela, i-sugar residue, inkunkuma ye-biogas, intsalela yoboya, njl.

3. Inkunkuma yezolimo: iindiza zezityalo, umgubo weembotyi zesoya, umgubo wecottonseed, njl.

4. Inkunkuma yasekhaya: inkunkuma yasekhitshini

5. i-sludge: i-sludge yasezidolophini, i-sludge yomlambo, i-sludge yokucoca, njl.

Umgca wokuvelisa i-disk granulation uhambele phambili, usebenza kakuhle kwaye usebenza, isakhiwo sesixhobo sihlangene, i-automation iphezulu, kwaye umsebenzi ulula, olungele ukuveliswa kobuninzi be-organic fertilizer.

1. Izinto ezikwaziyo ukubola kunye nokunxiba zisetyenziswa kuzo zonke izixhobo zomgca wokuvelisa.Akukho kukhutshwa kwenkunkuma emithathu, ukonga amandla kunye nokukhuselwa kwendalo.Ibaleka ngokuzinzileyo kwaye kulula ukuyigcina.

2. Umthamo wokuvelisa unokulungelelaniswa ngokweemfuno zabathengi.Ubume bomgca wemveliso yonke buhlangene, isayensi kunye nengqiqo, kwaye iteknoloji iqhubekile.

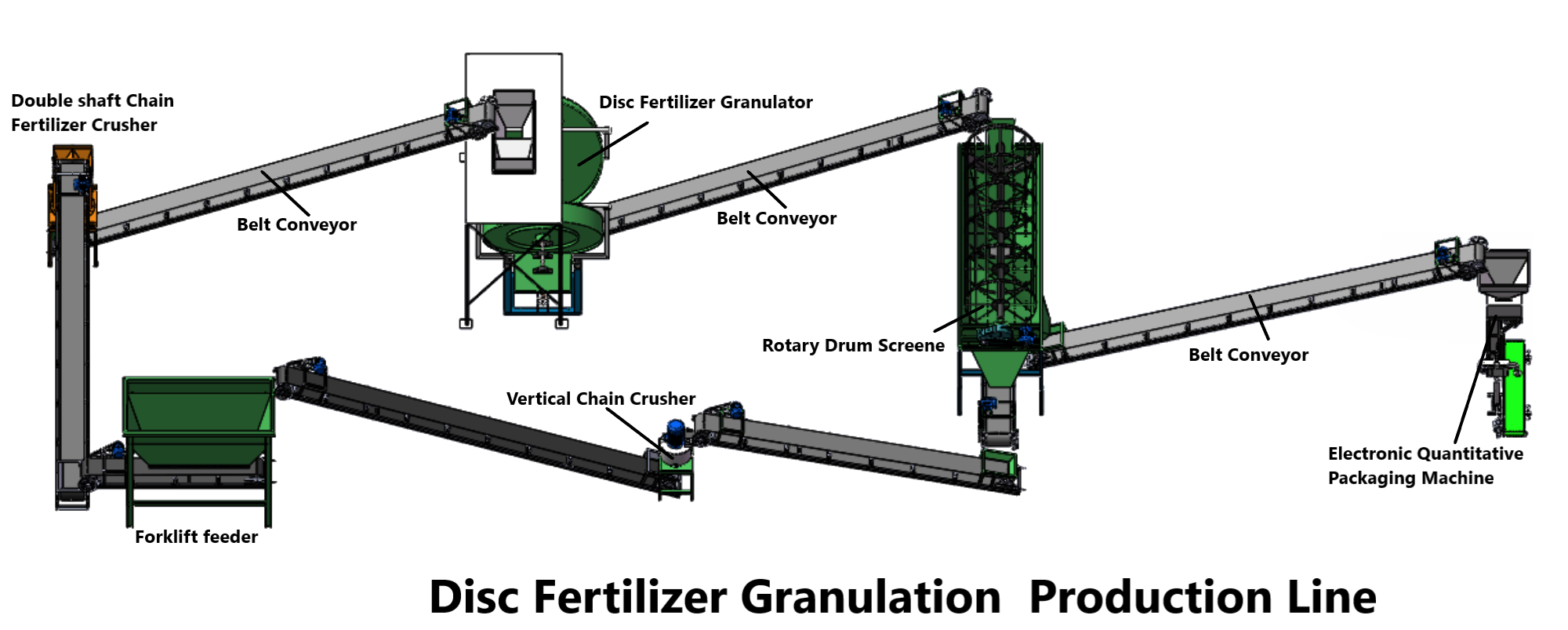

Isixhobo sokuvelisa idisk granulation sibandakanya indawo yokugcina izithako → blender (sirring) → umatshini wedisk granulation (igranulator) → umatshini we-roller we-sieve (ukwahlula iimveliso ezikumgangatho osezantsi kwiimveliso ezigqityiweyo) → isityumzi esithe nkqo setsheyini (ukwaphulwa) → umatshini wokupakisha ozenzekelayo (ukupakishwa) → ukuhambisa ibhanti ( ukudibanisa kwiinkqubo ezahlukeneyo).

Qaphela: lo mgca wemveliso ubhekiselele kuphela.

Ukuhamba kwenkqubo yomgca wokuvelisa idisk granulation ngokuqhelekileyo kunokwahlulwa ibe:

1. Inkqubo yezithako zezinto ezikrwada

Umlinganiselo ongqongqo wemathiriyeli ekrwada unokuqinisekisa ukusebenza kakuhle kwezichumiso.Izinto ezikrwada zibandakanya ilindle lezilwanyana, iziqhamo ezibolileyo, amaxolo, imifuno eluhlaza, isichumiso esiluhlaza, isichumisi solwandle, isichumiso sasefama, inkunkuma emithathu, iimicroorganisms kunye nezinye izinto ezimdaka zendalo.

2. Inkqubo yokuxuba izinto ezikrwada

Zonke izinto eziluhlaza zixutywe kwaye zixutywe ngokulinganayo kwi-blender.

3. Inkqubo eyaphukileyo

Isityumzi esithe nkqo setsheyini sityumza amaqhekeza amakhulu ezinto zibe ngamaqhekeza amancinci anokufikelela kwiimfuno zegranulation.Emva koko i-conveyor yebhanti ithumela izinto kumatshini we-disk granulation.

4. Inkqubo yegranulation

I-disk angle yomshini we-disk granulation ithatha isakhiwo se-arc, kwaye izinga lokubumba ibhola lingafikelela ngaphezu kwe-93%.Emva kokuba izinto zingene kwi-plate ye-granulation, ngokujikeleza okuqhubekayo kwediski ye-granulation kunye nesixhobo sokutshiza, izinto eziphathekayo zihlanganiswe ngokulinganayo ukuze zivelise amaqhekeza anesimo esifanayo kunye nesimo esihle.

5. Inkqubo yokuhlola

Izinto ezipholileyo zithunyelwa kumatshini we-roller we-sieve ukuze kuhlolwe.Iimveliso ezifanelekileyo zingangena kwindawo yokugcina impahla egqityiweyo ngokusebenzisa i-belt conveyor, kwaye inokupakishwa ngokuthe ngqo.Amasuntswana angafanelekanga aya kubuyela kwi-regrainate.

6. Inkqubo yokupakisha

Ukupakishwa yinkqubo yokugqibela yomgca wokuvelisa isichumiso.Imveliso egqityiweyo ipakishwe ngomatshini wokupakisha wobungakanani ngokuzenzekelayo.Umgangatho ophezulu wokuzisebenzela kunye nokusebenza okuphezulu akuphumeleli kuphela ukulinganisa okuchanekileyo, kodwa kunye nokugqibezela inkqubo yokugqibela.Abasebenzisi banokulawula isantya sokutya kwaye babeke iiparamitha zesantya ngokweemfuno zangempela.