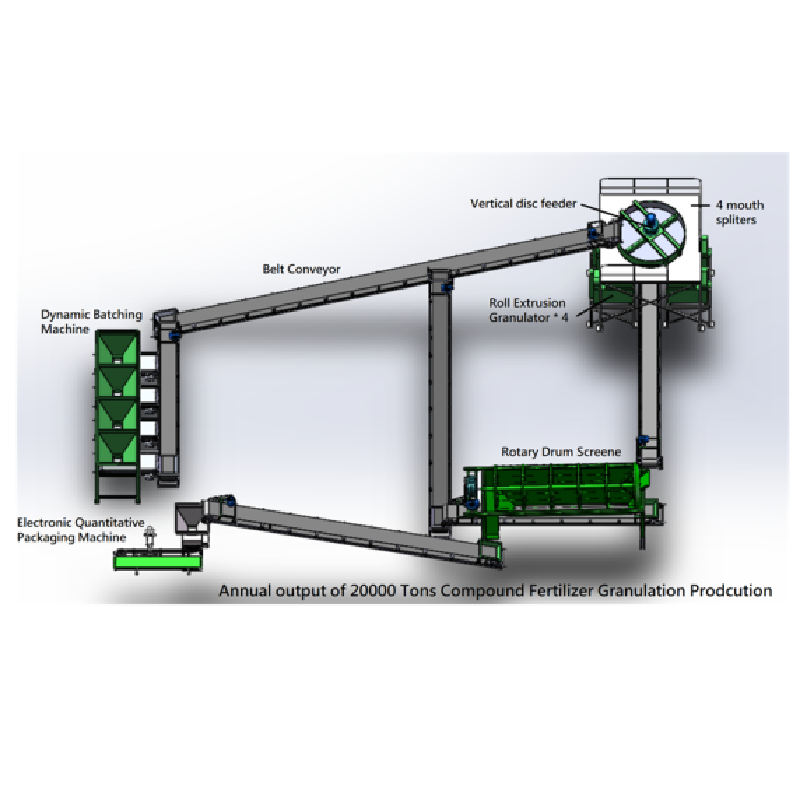

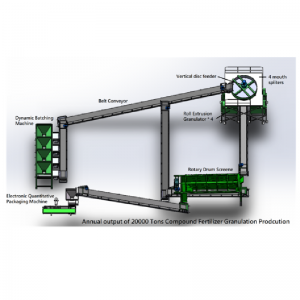

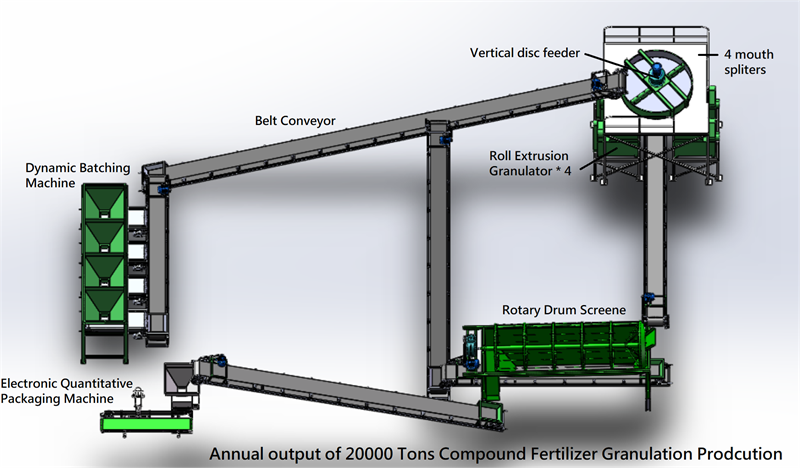

Umgca wokuvelisa isichumiso esidityanisiweyo kunye nemveliso yonyaka yeetoni ezingama-20,000.

Umgca wokuvelisa isichumisongemveliso yonyaka yeetoni ezingama-20,000.

Ngemveliso yonyaka yeetoni ezingama-20,000, inokuvelisa izichumisi ezihlanganisiweyo eziphezulu, eziphakathi kunye nezisezantsi ezigxininiswe kwizityalo ezahlukeneyo.Umgca wokuvelisa awufuni ukomisa, unotyalo-mali oluphantsi kunye nokusetyenziswa kwamandla aphantsi.

Iirola ezicinezelayo zomgca wokuvelisa isichumiso esixubeneyo zingayilwa zibe ziimilo ezahlukeneyo kunye nobukhulu ukuze zikhutshwe ukuze zivelise iigranules zobukhulu obuhlukeneyo kunye neemilo.

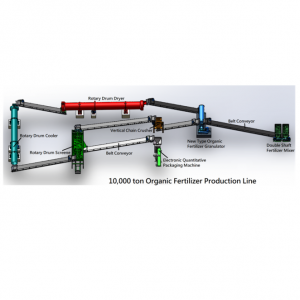

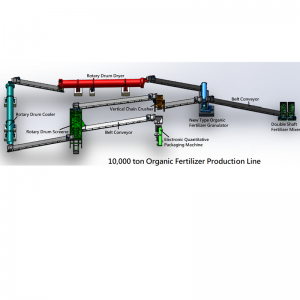

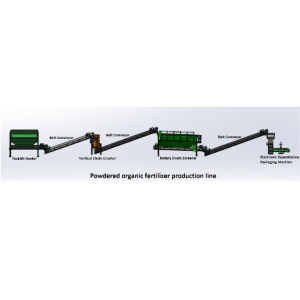

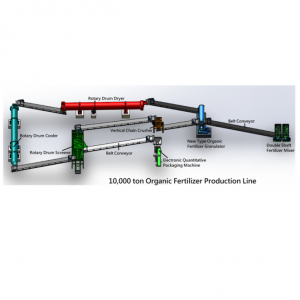

Iumgca wokuvelisa isichumiso esihlanganisiweyongemveliso yonyaka yeetoni ezingama-20,000 iphuculwe yiYizheng Heavy Industry, ishishini elikhethekileyo kuphando nophuhliso, imveliso kunye nokuthengiswa kwezixhobo zokuvelisa isichumiso.Ibonelela ngeseti epheleleyo yemigca yemveliso yesichumiso ephilayo somgquba wenkukhu, umgquba wehagu, umgquba wenkomo, kunye nomgquba weegusha kunye nemveliso yonyaka ye-10,000 ukuya kwi-200,000 yeetoni.Uyilo loyilo.

UmGaqo woMsebenzi :

Ngokuqhelekileyo, iumgca wokuvelisa isichumiso esiyintlanganiselangokubanzi iqulathe la macandelo alandelayo: inkqubo yokuxuba, inkqubo yegranulation, inkqubo yokutyumza, inkqubo yokuhlola, inkqubo yokugubungela kunye nenkqubo yokupakisha.

1. Umatshini wokuBambisa onamandla:

Izithako zezinto ezingaphezulu kwezintathu zinokuqhutywa.Umatshini wokudibanisa unezisele ezingaphezu kwezintathu, kwaye unokunyusa ngokufanelekileyo kwaye unciphise isisele ngokweemfuno zomthengi.Ekuphumeni kwesisele ngasinye, kukho umnyango we-elektroniki we-pneumatic.Phantsi kwesisele, ibizwa ngokuba yihopper, nto leyo ethetha ukuba umzantsi we hopper libhanti lokuhambisa.Kuthiwa i-hopper kunye ne-belt conveyor zixhonywe kwelinye icala le-lever yokuhambisa, enye isiphelo se-lever ixhunyiwe kwi-sensor ye-tension, kwaye i-sensor kunye ne-pneumatic control part ixhunyiwe kwikhompyutheni.Lo matshini wamkela ubunzima obuqokelelweyo bezikali ze-elektroniki, ezilawulwa ngokuzenzekelayo ngumlawuli we-batching, kwaye umlinganiselo wokulinganisa wezinto nganye ugqitywe ngokulandelelana.Ineenzuzo zesakhiwo esilula, ukuchaneka okuphezulu kwesithako, ukusebenza okulula kunye nokusetyenziswa okuthembekileyo.

2. ISityuli seChayini esithe nkqo:

Dibanisa izixhobo ezidityanisiweyo ezahlukeneyo ngokomlinganiselo othile kwaye uzibeke kwisityumzi nkqo chain.Izinto eziluhlaza ziya kutyunyuzwa zibe ngamancinci amancinci ukuhlangabezana neemfuno zenkqubo ye-granulation elandelayo.

3. I-disc feeder ethe nkqo:

Emva kokuba izinto eziluhlaza zityunyuziwe, zithunyelwa kwi-Vertical disc feeder, kwaye izinto eziluhlaza zixutywe kwaye zixutywe ngokulinganayo kumxube.Umgca wangaphakathi womxube we-polypropylene okanye ipleyiti yensimbi engenasici.Izinto ezinjalo eziluhlaza kunye ne-corrosion ephezulu kunye ne-viscosity akulula ukunamathela.Izinto ezixubileyo ziya kungena kwi-drum granulator.

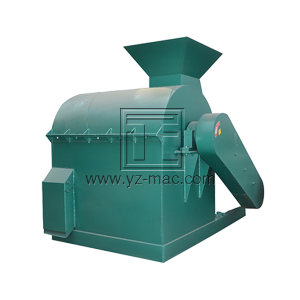

4. Roll Extrusion Granulator:

Ukwamkela iteknoloji ye-extrusion eyomileyo, inkqubo yokumisa iyashiywa.Ikakhulu ixhomekeke kuxinzelelo lwangaphandle, ukwenzela ukuba izinto zinyanzeliswe ukuba zinyanzeliswe zibe ziziqwenga ngokusebenzisa i-reverse roller clearances.Ubuninzi bokwenene bezinto eziphathekayo bunokwenyuka ngamaxesha angama-1.5-3, ngaloo ndlela ukufikelela kumlinganiselo othile wamandla.Ngokukodwa ezifanelekileyo kwiindawo zokwandisa ubunzima be-stack yemveliso.I-elasticity yokusebenza kunye noluhlu olubanzi lokuziqhelanisa lunokulungelelaniswa ngoxinzelelo lolwelo.Isixhobo asikho nje isayensi kwaye sinengqiqo kwisakhiwo, kodwa sinotyalo-mali oluncinci, impembelelo ekhawulezayo kunye neenzuzo ezilungileyo zoqoqosho.

5. I-Rotary Drum Screene:

Isetyenziselwa ikakhulu ukwahlula imveliso egqityiweyo kwizinto ezihlaziyiweyo.Emva kwe-sieving, amasuntswana afanelekileyo afakwe kumatshini wokusonga, kwaye amasuntswana angafanelekanga atyiswa kwi-crush chain chain ukuze enze i-granulated kwakhona, ngaloo ndlela ukuqonda ukuhlelwa kwemveliso kunye nokuhlelwa okufanayo kweemveliso ezigqityiweyo.Umatshini wamkela isikrini esidibeneyo sokugcinwa lula kunye nokutshintshwa.Ulwakhiwo lwayo lulula kwaye lugxothiwe.Ukusebenza ngokufanelekileyo kunye nozinzo sisixhobo esiyimfuneko kwimveliso yesichumisi.

6. Umatshini wokuPakisha woMbane woMbane:

Emva kokuba iinqununu zihlolwe, zihlanganiswe ngumatshini wokupakisha.Umatshini wokupakisha unomgangatho ophezulu wokuzenzekelayo, ukudibanisa ubunzima, i-suture, ukupakisha kunye nokuthutha, okuqonda ukupakishwa kobuninzi okukhawulezayo kwaye kwenza inkqubo yokupakisha isebenze ngakumbi kwaye ichanekile.

7. Ukuhambisa ibhanti:

Umthumeli udlala indima ebalulekileyo kwinkqubo yokuvelisa, kuba idibanisa iindawo ezahlukeneyo zomgca wemveliso wonke.Kulo mgca wokuvelisa isichumiso esihlanganisiweyo, sikhetha ukukubonelela ngebhanti yokuhambisa.Xa kuthelekiswa nezinye iintlobo zokuhambisa, iibhanti zokuhambisa zinokhuselo olukhulu, nto leyo eyenza ukuba inkqubo yakho yokuvelisa isebenze kakuhle kwaye ibe yeyongayo.

Ukufumana izisombululo ezithe vetshe okanye iimveliso, nceda uqaphele iwebhusayithi yethu esemthethweni:

https://www.yz-mac.com/20000-ton-compound-fertilizer-production-linec/